The latch is first swung into place. Second, the latch compresses a gasket against the frame. Read More…

Cabinet latches are our specialty! We are located in Torrington, CT but we are committed to serving our customers wherever they may need us! All of our products go through extensive and intensive testing to ensure that we are providing our customers with only the best possible products. For more information on what we can do for you visit our website today or get in touch via email or telephone!

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

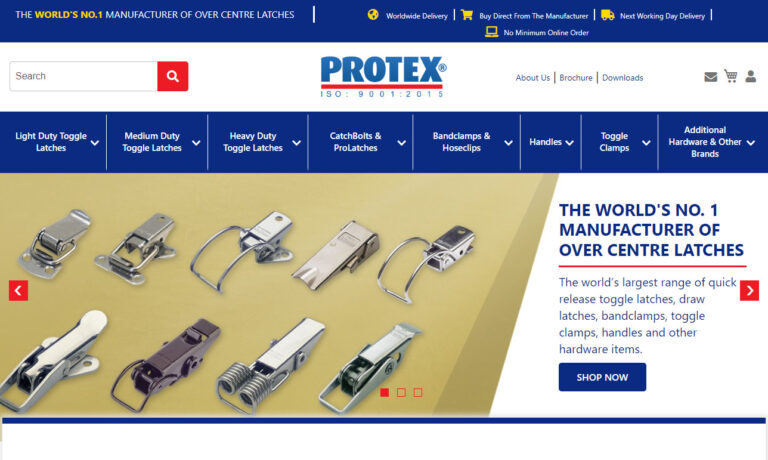

At PROTEX® we offer light to heavy-duty fasteners, handles, flush latches, case fittings, bandclamps, catch plates and more. We manufacture a large range of over centre fasteners often known as draw latches/toggle clamps/catches/over centre toggle fasteners.

More Compression Latch Manufacturers

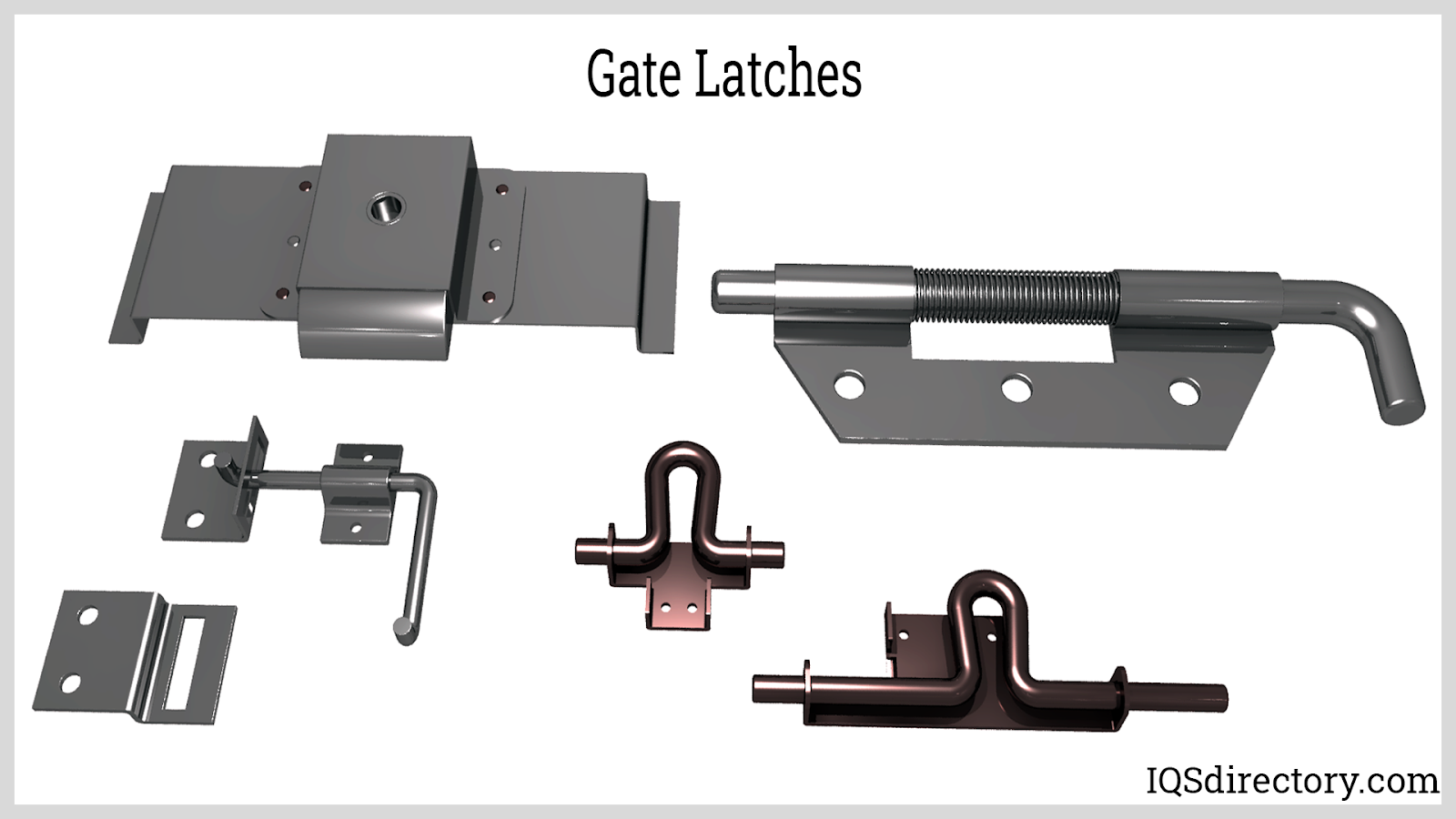

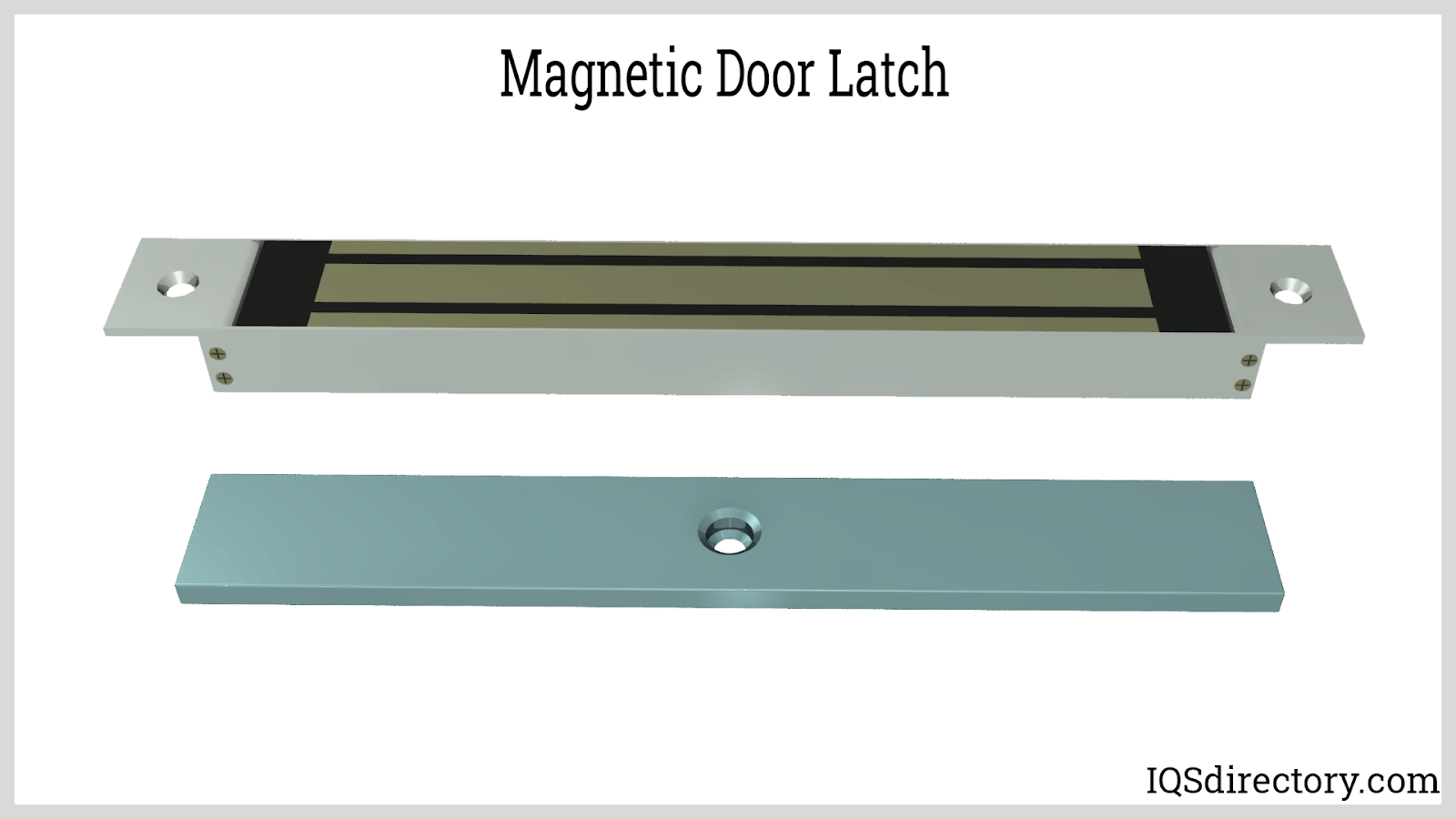

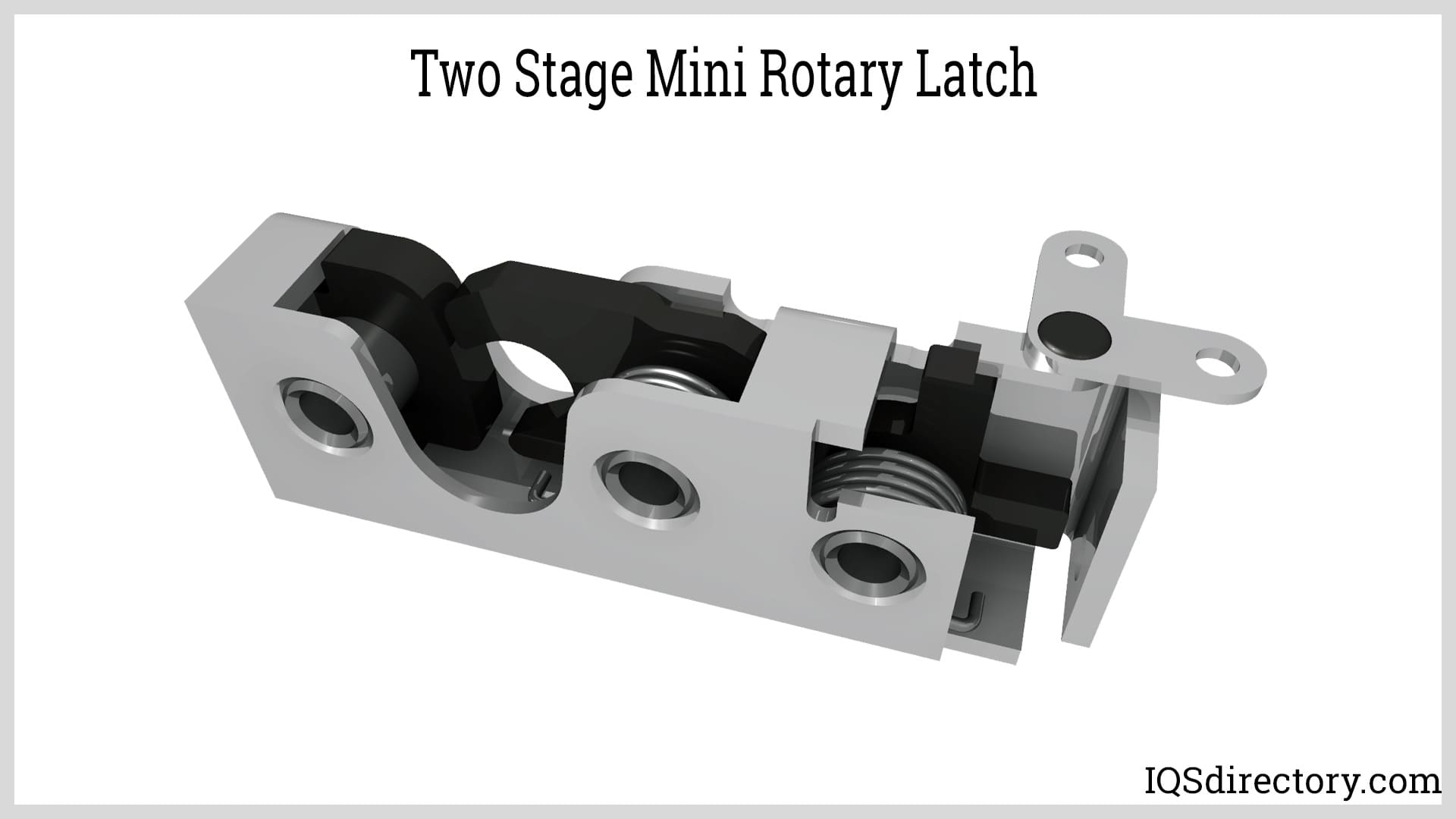

Compression latches are mechanical closure devices that are used in applications requiring sealed closing and protection from the elements. Compression latches are used in many different industries as the ability to seal the frame surrounding the latch makes compression latches useful closing options. Areas such as computers and electronics, industrial equipment and machinery, electronic enclosures, vehicular systems and construction equipment all use compression latches in one form or another to seal and protect.

In addition, the compression seal is able to reduce vibrations and shock, an important feature in applications such as industrial equipment and off-highway vehicles that are exposed to rough terrain or motion. Depending on the materials employed in the fabrication of compression latches, they can also provide a watertight seal and therefore compression latches are used widely in outdoor and marine equipment.

Panel latches, T-latches, lift and turn latches, lever, vice action, trigger and round latches are some of the many variations of compression latches. Depending on the intended use of the latch, the amount of compression achieved is variable and can be pre-set or adjustable for more flexibility. An added benefit of adjustable compression latches is that they are able to take up the slack as the seal or gasket begins to wear down with age.

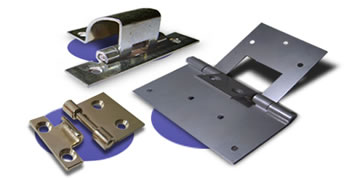

The range of materials used in the fabrication of compression latches includes stainless steel, die cast zinc or steel. While stainless steel latches are naturally durable and corrosion resistant, common top coatings for other materials include chrome finish and black powder coat. Using a topcoat on compression latches may be both for appearance and protective purposes.

Most metals are susceptible to damage over time when exposed to the elements and therefore, coatings ensure a longer product life and greater product reliability. Compression latches all have a lever or a knob that is used to fasten the latch. In automated compression latches, the lever causes compression on the gasket, creating the sealed closure.

Commonly used on doors and compartments such as cabinets or storage facilities, compression latches can have numerous activation options. The compression factor which is activated most often by a half turn motion can be achieved by hand, key or tool activated compression. Compression latches are available in a broad range of standard sizes and capabilities, and yet are also available to meet custom specifications and requirements. They can be supplied either assembled or unassembled depending on their intended location and application.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services