A two-part latch called a “draw latch” contains an arm on one side that may connect to the other half; as it closes, the clasp draws the two sides together. Draw latches hold two components firmly together temporarily until they are driven apart by a wedge, wing nut, or hand. They operate like an ordinary hinge that can be pulled open by hand and employs tension to retain two things tightly connected—frequently applied to windows, toolboxes, chests, and crates. Read More…

Cabinet latches are our specialty! We are located in Torrington, CT but we are committed to serving our customers wherever they may need us! All of our products go through extensive and intensive testing to ensure that we are providing our customers with only the best possible products. For more information on what we can do for you visit our website today or get in touch via email or telephone!

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

At PROTEX® we offer light to heavy-duty fasteners, handles, flush latches, case fittings, bandclamps, catch plates and more. We manufacture a large range of over centre fasteners often known as draw latches/toggle clamps/catches/over centre toggle fasteners.

More Draw Latch Manufacturers

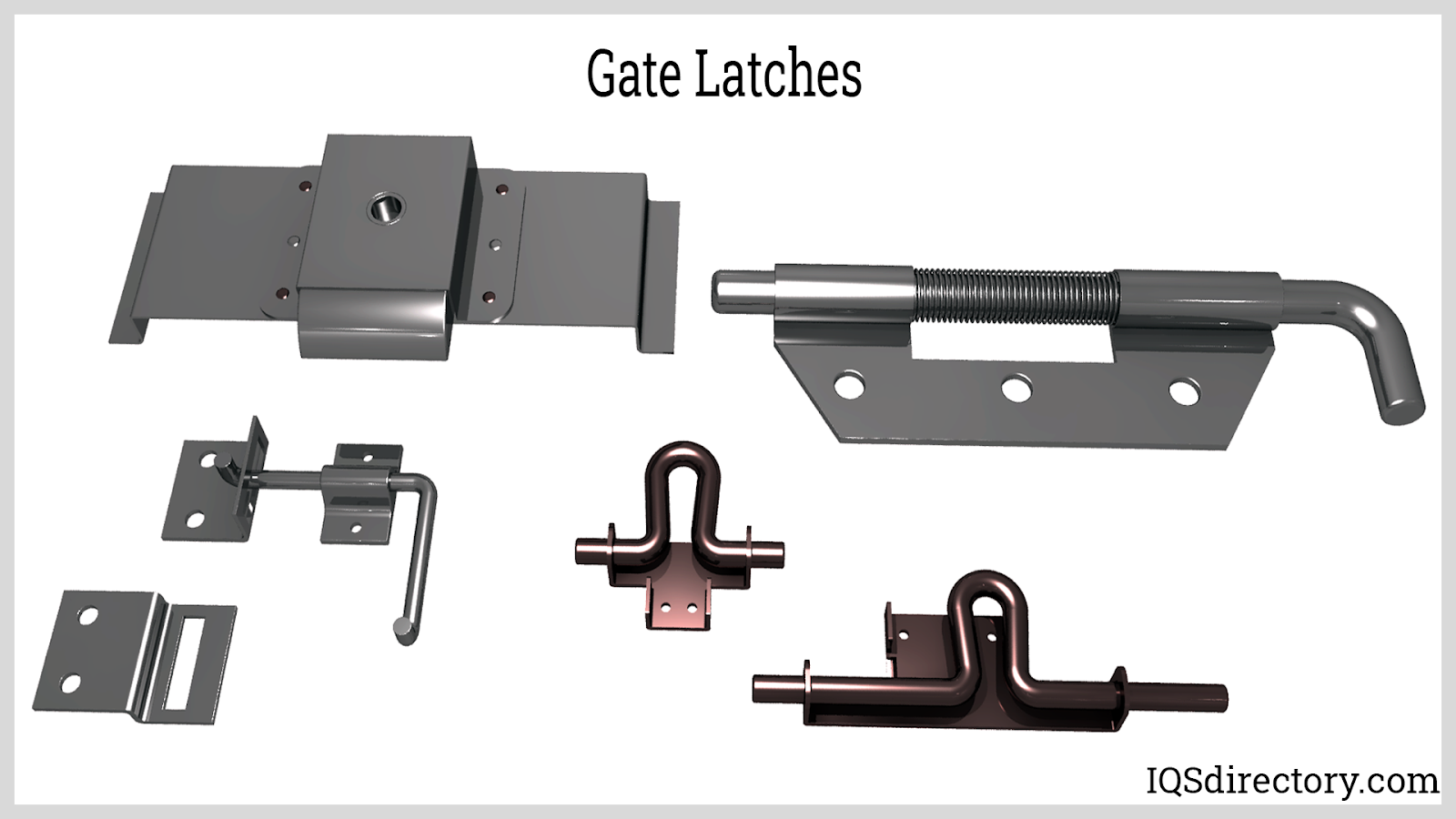

Any door, panel, or enclosure can have its draw latches changed to fit it and have a push-pull mechanism that can be opened with little effort while remaining snugly secured when the user is not holding it. Some types also come with integrated or external hinges for added versatility. Because of how they function, draw latches are often referred to as "toggle clamps" or "over-center fasteners." Depending on their intended application, draw latches are available in a range of sizes, load capacities, materials, and forms to suit diverse industrial and commercial needs. Nevertheless, all draw latches share a few design elements that make them easy to install without additional specialized equipment, making them a top choice for OEMs and end users seeking quick latch solutions.

What Is a Draw Latch? Understanding the Working Principle

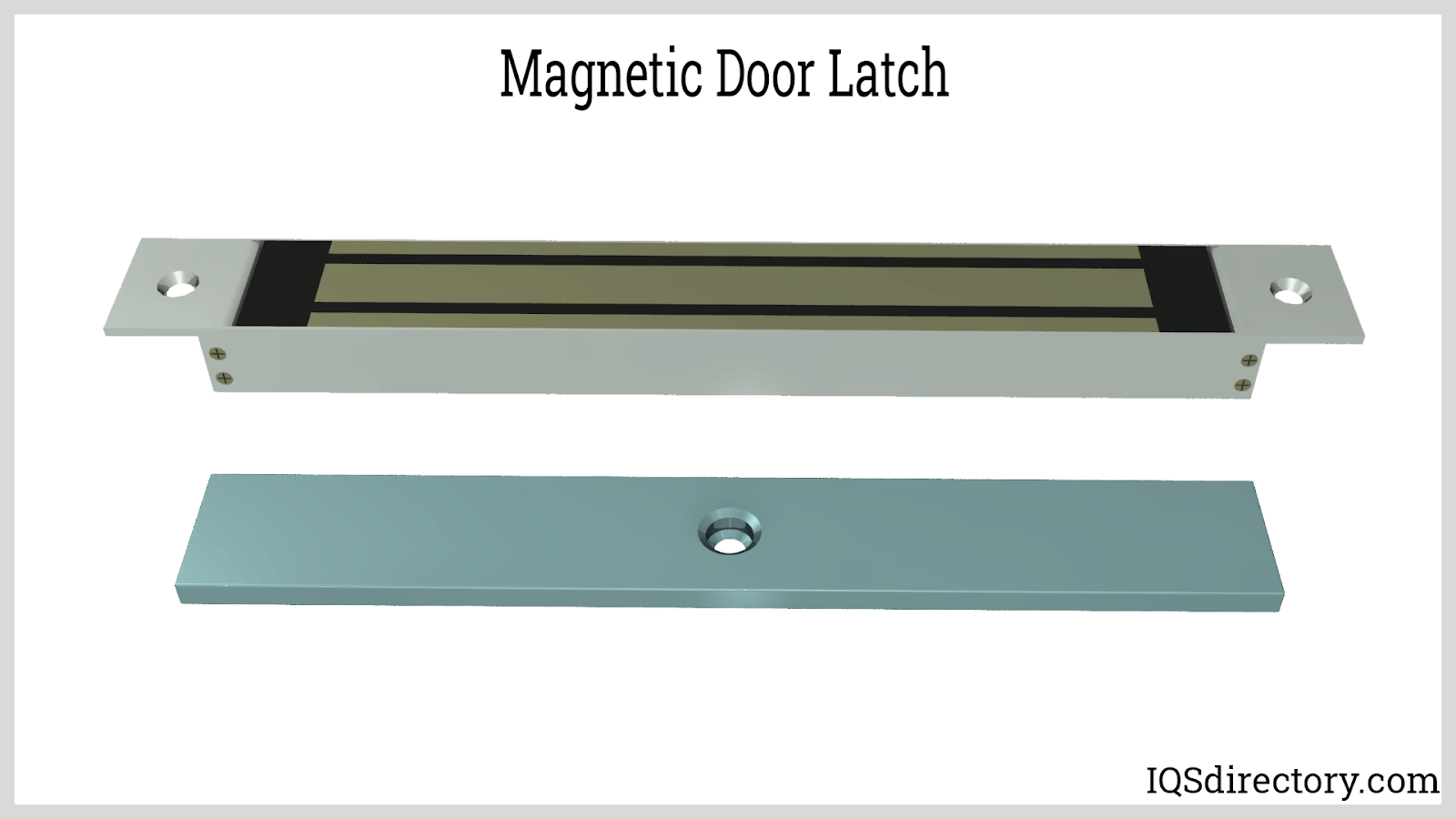

If you are searching for information about how draw latches operate, you're in the right place. Draw latches are unique mechanical fasteners designed to create and maintain tension between two adjoining surfaces, such as doors, panels, or machine enclosures. They can be accessed from either side of the door or panel, providing both convenience and security. In a typical draw latch assembly, the blade and keeper are the two core components that, when drawn together, produce the necessary tension to secure the application.

The keeper is a hooked plate that links securely to the blade, which is a small plate or arm. These two elements are tightly joined by a hinge or pivot mechanism between them. When the handle is pulled, the blade draws the keeper in, locking the latch and ensuring a secure closure. Many modern draw latches feature ergonomic handles, corrosion-resistant finishes, and tool-less actuation for operator ease. Draw latches can be locked or unlocked with a single motion, which makes them ideal for applications requiring frequent access as well as safety and vibration resistance.

Depending on the purpose, the installation may be horizontal or vertical. Draw latches can be installed on a wide range of materials, including painted or powder-coated surfaces, galvanized or stainless steel, zinc-plated metal, plastics, and even padlocks for additional security. In addition, draw latches can significantly reduce machine noise and vibration when applied properly, contributing to workplace safety and equipment longevity.

Types of Draw Latches: Finding the Right Latch for Your Application

Choosing the best draw latch for your application can be challenging with so many options available. Each type offers unique features suited to specific use cases, load requirements, and environmental conditions. Are you searching for a latch that provides adjustable tension? Need a concealed latch for aesthetic applications? Below are the main types of draw latches to consider:

Adjustable Draw Latches

Adjustable draw latches are designed for applications where the required tension may vary or where compensation for gasket compression, thermal expansion, or wear is needed. The arm of adjustable draw latches rotates around its hinge pin and is secured by a bolt or screw, allowing the user to modify the tension to fit the application. These are ideal for enclosures, HVAC panels, and machinery covers where a tight, customizable seal is critical. Industries such as telecommunications, electronics, and transportation often rely on adjustable draw latches for their adaptability and ease of maintenance.

Under-Center Draw Latches

Under-center draw latches are frequently employed where latching occurs out of a plane or where a low-profile latch is required. The hook keeper prevents the gate or panel from opening accidentally, providing reliable closure in demanding environments. After the latch is positioned on its hinge, the keeper is fastened by welding, riveting, or bolting it in place for permanent, tamper-resistant installation. A full rotation in either direction can only open the latch center; it will not open unless its keeper is released from one or both sides. Under-center latches are commonly used in transportation, industrial equipment, and heavy machinery for their robust holding strength and safety features.

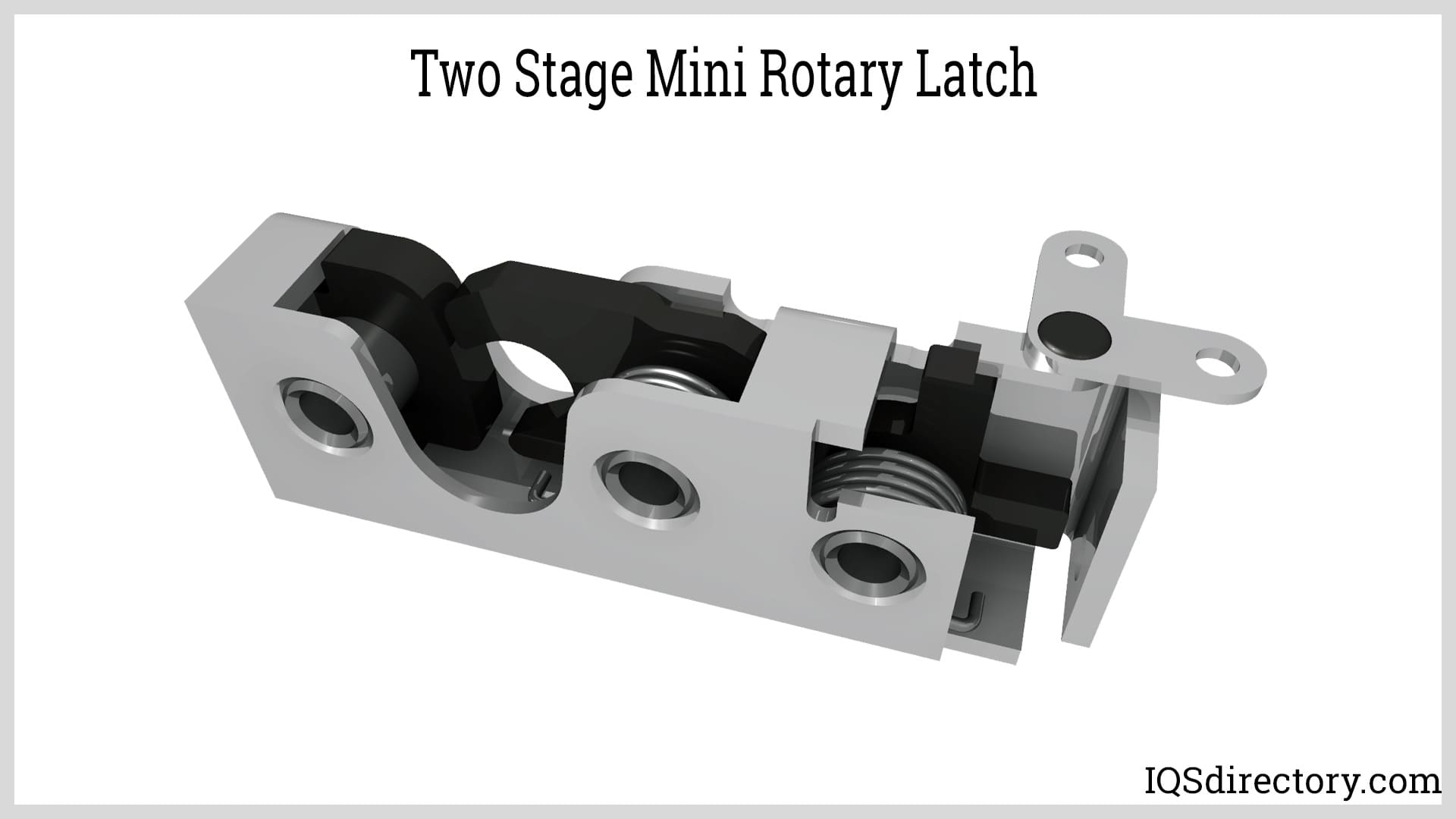

Over-Center Draw Latches

Over-center draw latches are among the most popular latch types for gates, access panels, truck bodies, and industrial cabinets that must open perpendicular to their hinges. This style of draw latch features a pull handle attached to the middle, enabling both quick opening and secure closure when not in use. The over-center action ensures that the latch remains closed under vibration and shock, making it ideal for high-traffic or mobile applications. Each side's top houses the hinge pin, which can be welded or bolted in after installation for added strength and durability in challenging environments.

Concealed Draw Latches

If your application demands an aesthetically pleasing appearance or tamper-resistance, concealed draw latches are an excellent choice. These latches are often installed inside panels that are butted together, using tool actuation to gradually draw the panels together. The rotating arm with an enclosed center can be extended outward by its draw handle, allowing for simple access, while a metal hook on one side ensures secure retention. The hook keeper prevents accidental unlatching, even if the arm is pulled out too far. Typical uses include architectural panels, high-end cabinetry, marine compartments, and electronics enclosures where visible hardware is undesirable.

Pull Draw Latches

Pull draw latches are ideal for scenarios where fast, one-handed operation is necessary. The arm is hoisted into position by a handle attached at one end, then fastened using a hook keeper on the other side to prevent accidental opening. These latches are widely used in toolboxes, storage cases, portable equipment, and lightweight doors where frequent access is required. Their simple design and reliable performance make them a staple in consumer products as well as industrial settings.

Flexible Draw Latches

Flexible draw latches feature a metal or polymer band that can be easily stretched over the hook keeper on either side. When tension is applied, the latch securely locks into place, providing reliable closure even under vibration. The gate or panel can only be opened by disengaging both hooks simultaneously, making accidental opening less likely. Flexible draw latches are commonly used in outdoor equipment, marine environments, and applications where flexibility and weather resistance are critical.

Typical Applications of Draw Latches: Where Are Draw Latches Used?

Draw latches are indispensable components across a wide variety of industries and products. Their versatility, strength, and ease of use make them a popular choice for OEM manufacturers, maintenance teams, and end users alike. Wondering if draw latches are right for your project? Explore just a few of the many applications below:

HVAC Systems

In HVAC systems (heating, ventilation, and air conditioning), draw latches are frequently used to fasten large components such as furnace doors, compressor covers, and condenser enclosures. They are also installed on access cabinets that house electrical controls and sensitive equipment. By using draw latches, facilities managers can provide secure, tool-free access for maintenance while safeguarding against unauthorized tampering. Their vibration-dampening properties also help reduce noise and prolong equipment lifespan.

Storage Compartments and Lids

Draw latches are commonly used to secure lids and storage compartments on containers such as toolboxes, ammunition boxes, shipping cases, and portable storage units. They provide a robust closure that prevents accidental opening during transport, while enabling quick access when needed. Many manufacturers choose corrosion-resistant draw latches for outdoor or marine storage solutions to ensure long-term performance.

Exhibits and Displays

In museums, trade shows, and retail displays, draw latches are used to join backing panels, secure modular furniture, and protect wiring or lighting installations. Their tamper-resistant design offers both support and security, preventing unauthorized access to valuable or sensitive components. The ease of installation and removal makes them ideal for temporary or reconfigurable displays, as well as permanent museum exhibits and interactive installations.

Lawn and Garden Equipment

For lawn and garden equipment, draw latches provide enclosure security for outdoor storage boxes, lawnmower covers, greenhouses, animal shelters, and other structures. Their weather-resistant materials and finishes ensure reliable performance in challenging environments. Homeowners, landscapers, and agricultural professionals rely on draw latches to secure gates, panels, and access doors, keeping equipment and animals safe from the elements and unauthorized access.

Automotive and Transportation

Automotive and transportation industries use draw latches to secure hoods, tailgates, truck bodies, service panels, cargo containers, and RV compartments. Their ability to withstand vibration and provide consistent closure under varying loads makes them essential for road, rail, and marine vehicles. Looking for automotive latches that meet DOT or OEM specifications? Many manufacturers offer draw latches tested for compliance and durability.

Industrial Machinery and Enclosures

Draw latches play a critical role in securing machine covers, electrical enclosures, generator housings, and safety guards in industrial settings. By providing reliable closure and vibration resistance, they help maintain safe operating conditions and protect sensitive components from dust, moisture, and unauthorized access. For hazardous environments, stainless steel or reinforced polymer draw latches offer additional chemical and corrosion resistance.

Electronics and Telecommunications

In electronics and telecom applications, draw latches secure server racks, network cabinets, battery enclosures, and portable equipment cases. They allow for fast, tool-free access during maintenance while ensuring that panels remain tightly closed, protecting internal circuitry from electromagnetic interference (EMI), dust, and moisture. For applications requiring EMI shielding or grounding, specialized draw latches with conductive coatings are available.

Marine and Recreational Vehicles

Boats, yachts, RVs, and campers utilize draw latches to secure hatches, access panels, and storage compartments. Marine-grade stainless steel or polymer draw latches provide superior resistance to saltwater corrosion and UV exposure, ensuring long service life in harsh outdoor conditions. Wondering which latch is best for your marine application? Consider factors such as material, load rating, and ease of use when selecting a draw latch for your vessel or vehicle.

Key Benefits of Draw Latches: Why Choose a Draw Latch?

Draw latches offer a range of advantages over other fastening solutions, making them a popular choice in demanding industrial, commercial, and consumer applications. Looking for reasons to choose draw latches? Here are some of their most significant benefits:

- Simple to specify and easy to install: Draw latches require minimal tools and expertise for installation, saving time and labor costs.

- Mechanical advantage: Draw latches compress gaskets and ensure a tight, vibration-resistant seal, even in high-load or high-vibration environments.

- Wide selection of materials and finishes: Available in stainless steel, zinc, aluminum, and a variety of coatings to suit any environment, including marine, chemical, and outdoor applications.

- Securely draws panels together: Maintains consistent tension for reliable closure and optimal sealing performance.

- Customizable for size and strength: Options available for light-duty to heavy-duty applications, with adjustable and fixed-tension models to match your requirements.

- Versatile design options: Choose from concealed, adjustable, over-center, and flexible designs to fit your project's aesthetic and functional needs.

- Enhanced safety and security: Draw latches can be combined with locks or safety seals for added protection against unauthorized access.

- Tool-free operation: Many draw latches offer ergonomic handles or quick-release mechanisms for easy access and operation.

Potential Drawbacks of Draw Latches: What to Consider

While draw latches are highly effective, there are also some considerations to keep in mind when selecting the best latch for your needs. Are draw latches right for every application? Here are a few potential disadvantages:

- Susceptibility to tampering: Standard draw latches can be manipulated easily if not combined with additional security features, such as padlocks or tamper-evident seals.

- Regular maintenance required: Moving parts may require occasional lubrication, cleaning, or adjustment to ensure continued performance, especially in harsh or outdoor environments.

- Load limitations: Some draw latches are not suitable for very high-load or structural applications—ensure you select a model rated for your specific load and safety requirements.

- Potential for misalignment: Poor installation or repeated overloading can lead to misalignment, reducing effectiveness and longevity.

How to Choose the Right Draw Latch: Decision Factors and Buying Guide

Selecting the right draw latch or toggle latch involves careful consideration of several key factors. Looking for advice on what to consider when buying a draw latch? Here’s a quick guide to help you make an informed decision:

- Application requirements: Consider the type of access (frequent or infrequent), the load the latch must withstand, and whether vibration or environmental exposure is a concern.

- Material compatibility: Choose latches made from materials compatible with your enclosure or panel—stainless steel for corrosion resistance, zinc for cost-effectiveness, or specialty polymers for weight savings.

- Environmental conditions: Will the latch be exposed to chemicals, saltwater, extreme temperatures, or UV radiation? Select finishes and materials designed for those environments.

- Security needs: Does your application require tamper resistance or lockability? Look for draw latches with integrated locks or provisions for padlocks.

- Ease of use: Ergonomic handles, tool-less operation, and quick-release features can enhance user experience and safety.

- Compliance and certifications: For regulated industries (e.g., automotive, food processing), ensure the latch meets relevant standards and certifications.

- Size and style: Ensure the latch's dimensions and mounting style fit your application, whether you need a low-profile concealed latch or a heavy-duty exterior latch.

Frequently Asked Questions About Draw Latches

Looking for quick answers about draw latches? Here are some common questions:

- What is the difference between a draw latch and a toggle latch? While often used interchangeably, "toggle latch" typically refers to any latch that uses an over-center action, while "draw latch" specifically describes latches designed to pull two surfaces tightly together.

- Can draw latches be locked? Many draw latches feature provisions for padlocks, security seals, or integrated locking mechanisms to prevent unauthorized access.

- How do I install a draw latch? Most draw latches are surface-mounted using screws, bolts, or rivets. Always follow manufacturer instructions for proper alignment and secure installation.

- Are there corrosion-resistant or weatherproof draw latches? Yes! Stainless steel, zinc-plated, and polymer draw latches are available for outdoor, marine, and corrosive environments.

- Where can I buy high-quality draw latches? Use our directory of draw latch manufacturers to compare options, request samples, and obtain quotes directly from reputable suppliers.

Choosing the Proper Draw Latch Manufacturer

To ensure you achieve the most productive outcome when purchasing draw latches from a reputable manufacturer or supplier, it is important to compare several companies using our comprehensive directory of draw latch manufacturers. Each draw latch manufacturer has a detailed business profile page highlighting their areas of expertise, certifications, production capabilities, materials offered, and industries served. You can also use our contact form to communicate directly with manufacturers for more information, request product samples, or obtain a custom quote tailored to your requirements.

Review each draw latch business website using our patented website previewer to quickly learn what each company specializes in, including value-added services such as custom engineering, private labeling, bulk pricing, or expedited shipping. Then, use our simple RFQ form to contact multiple draw latch companies with the same form—saving you time and streamlining your sourcing process.

Ready to find the best draw latch for your application? Start your search today using our draw latch manufacturer directory or request a quote from top suppliers. Whether you need standard toggle latches, custom over-center fasteners, or specialized industrial latches, you'll find the right solution to meet your needs.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

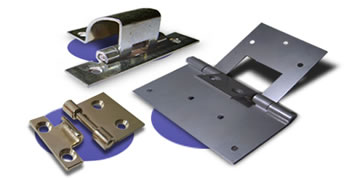

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services