While latches can be made of many different materials, plastic is commonly used for latch components. Plastic latches are used in industrial, commercial, domestic and agricultural settings. Read More…

Cabinet latches are our specialty! We are located in Torrington, CT but we are committed to serving our customers wherever they may need us! All of our products go through extensive and intensive testing to ensure that we are providing our customers with only the best possible products. For more information on what we can do for you visit our website today or get in touch via email or telephone!

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

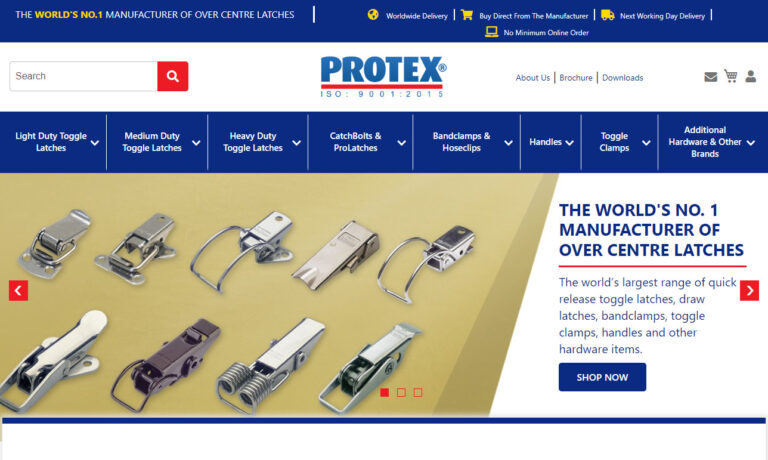

At PROTEX® we offer light to heavy-duty fasteners, handles, flush latches, case fittings, bandclamps, catch plates and more. We manufacture a large range of over centre fasteners often known as draw latches/toggle clamps/catches/over centre toggle fasteners.

More Plastic Latch Manufacturers

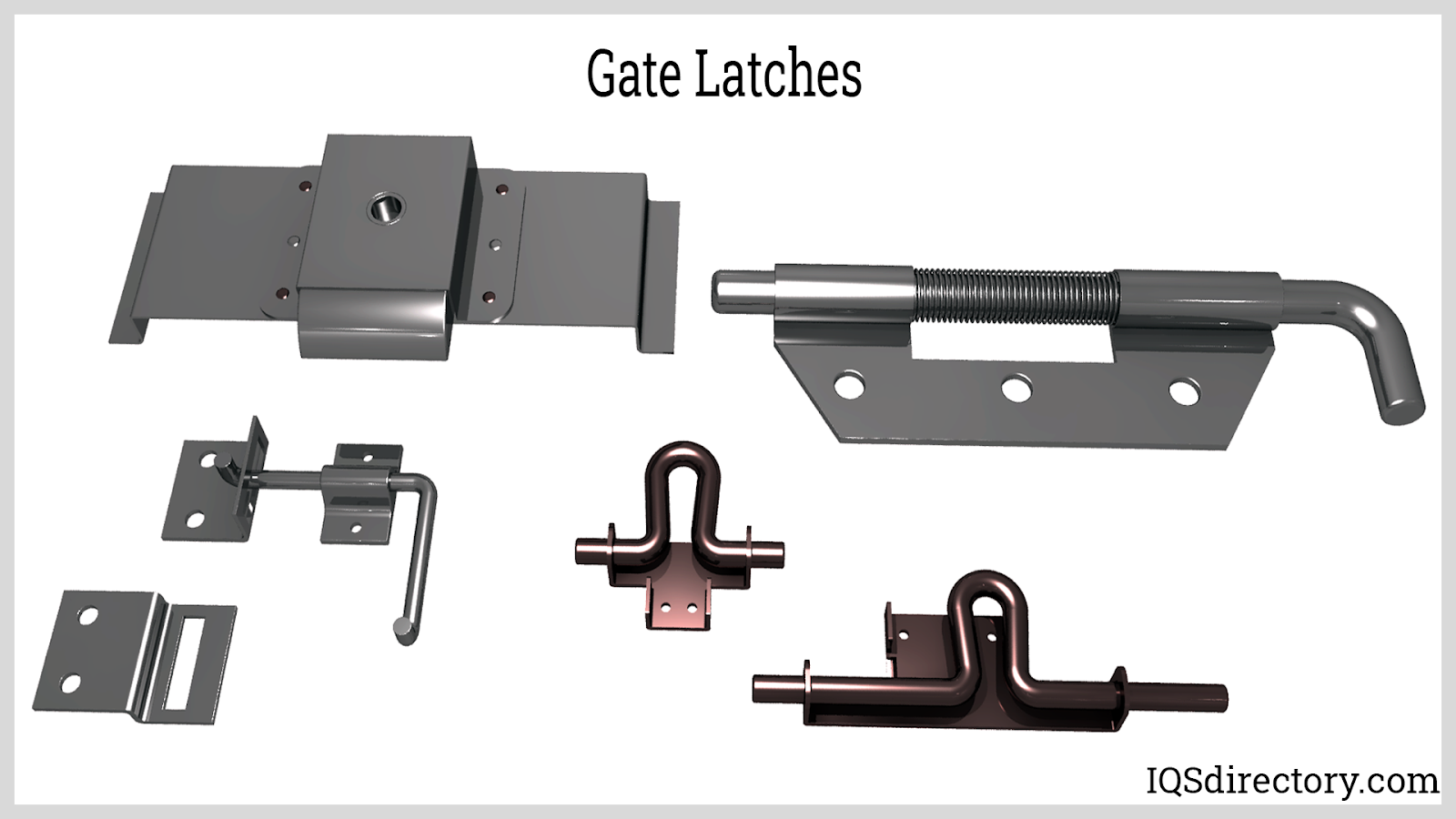

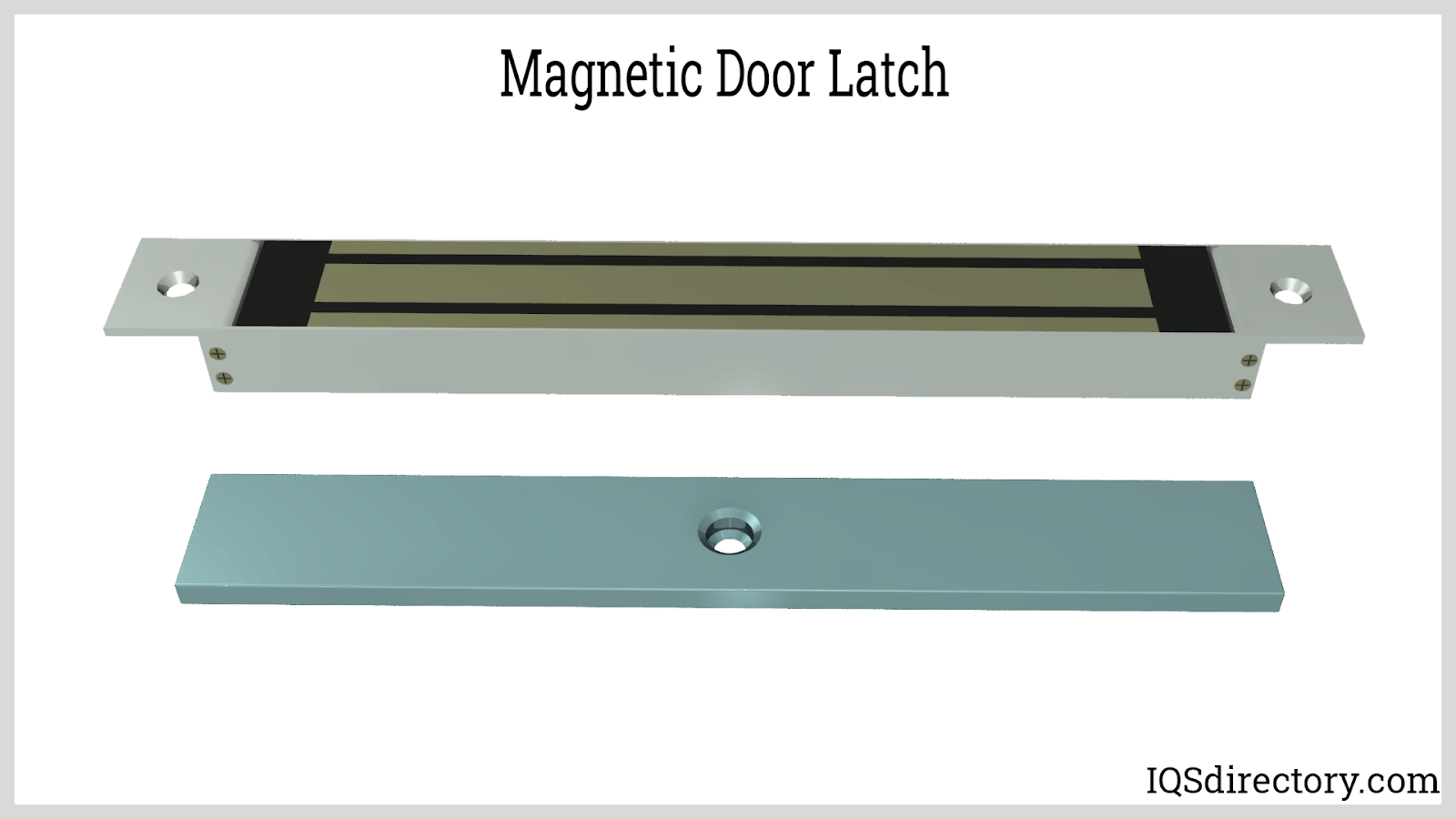

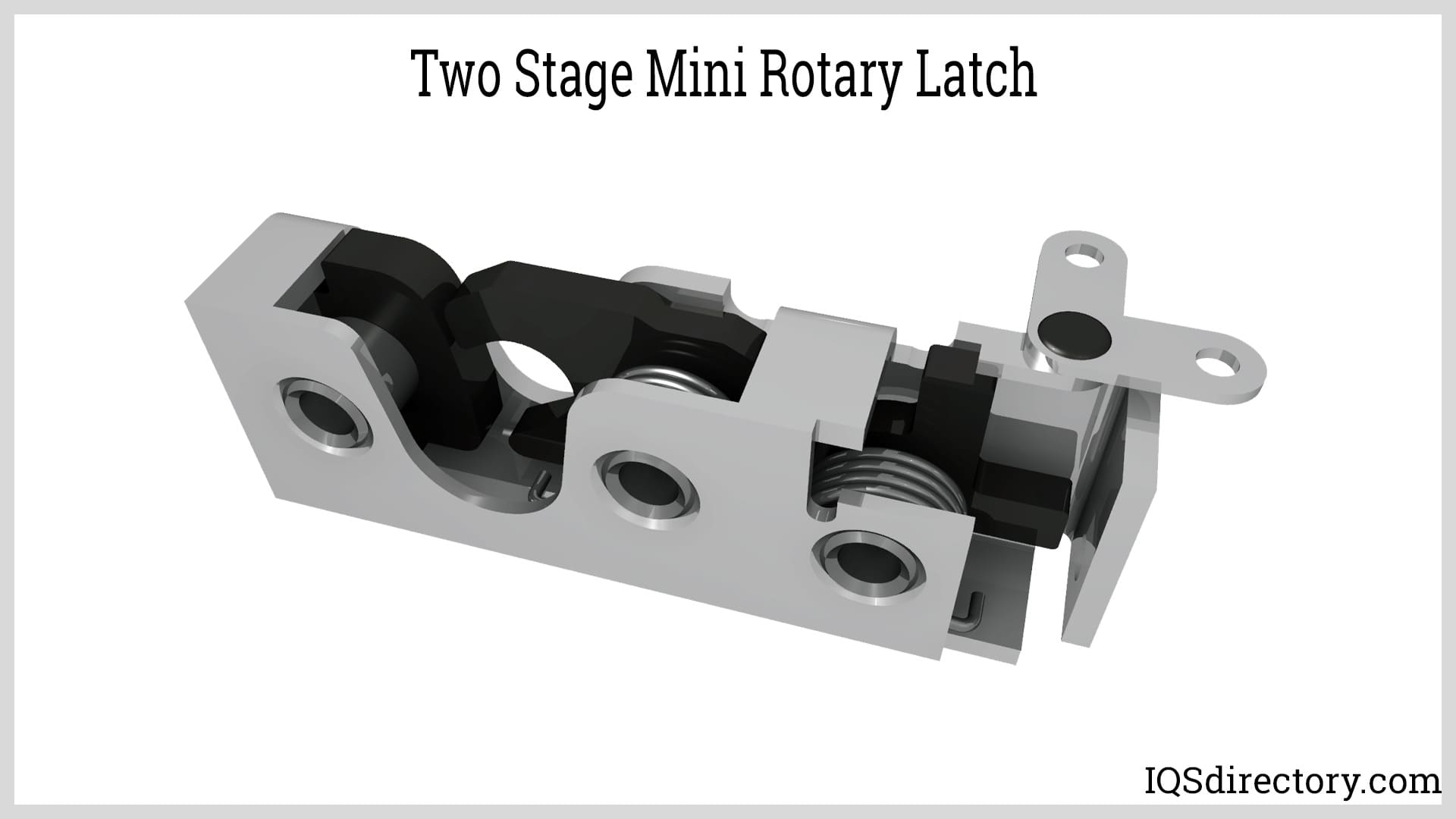

Plastic latches are most often utilized in applications which do not require high strength or durability in order to provide an effective closure. While many door latches and gate latches contain components of plastic, solid plastic latches are incorporated often in utility boxes, cabinets or storage compartments.

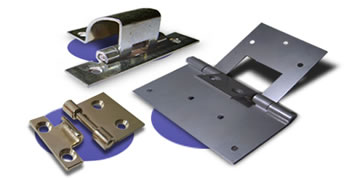

Latches are used to join two adjacent surfaces with the possibility or frequent and easy securing and disengaging. While industrial latches are most often made of strong metals, the use of plastic in latch manufacturing provides added impact resistance. This property combined with the corrosion resistance of plastic is important to increasing the longevity of exposed latches.

ABS, silicon and thermoplastics such as nylon 6/6 and polytherimide are just a few examples of frequently used plastics. Thermoplastics are used as they are easily shaped from molten form into durable and hard-wearing components. Plastic latches are well suited to many possible latch designs and are most often manufactured using injection molding or a similar technique to form the latch components.

In injection molding, the plastic resin, typically in pellet form, is heated until molten, and then injected into a preformed mold. Once in the mold cavity, the plastic is allowed to cool and set and is then ejected as the finished component. Stamping or machining may also be used to manufacture plastic latches. Depending on the quality of the molding, or stamping process, secondary machining may be required to ensure a piece is finished.

There are many benefits to working with and using latches made of plastic or with plastic components. Plastic latches are water and corrosion resistant and thus are widely used in marine and outdoor applications. The plastic components of other latches are integral in latches that require some give and flexibility that metals cannot offer.

Draw latches, for example, commonly use plastic in the strap mechanism of the latch. Plastics are not always flexible, however, and can also offer strength and rigidity. In applications such as doors, drawers, compartments and lids, life vests and a variety of cabinetry uses, plastic latches provide a simple and cost-effective closure solution to closure requirements.

While plastic may not be as strong as many metal alternatives, the growing diversity in types of thermoplastics makes them suitable to the many different types of latches available. Plastic is also able to adjusted in terms of color and finish in order to incorporate it more fully into its finished product or placement.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services