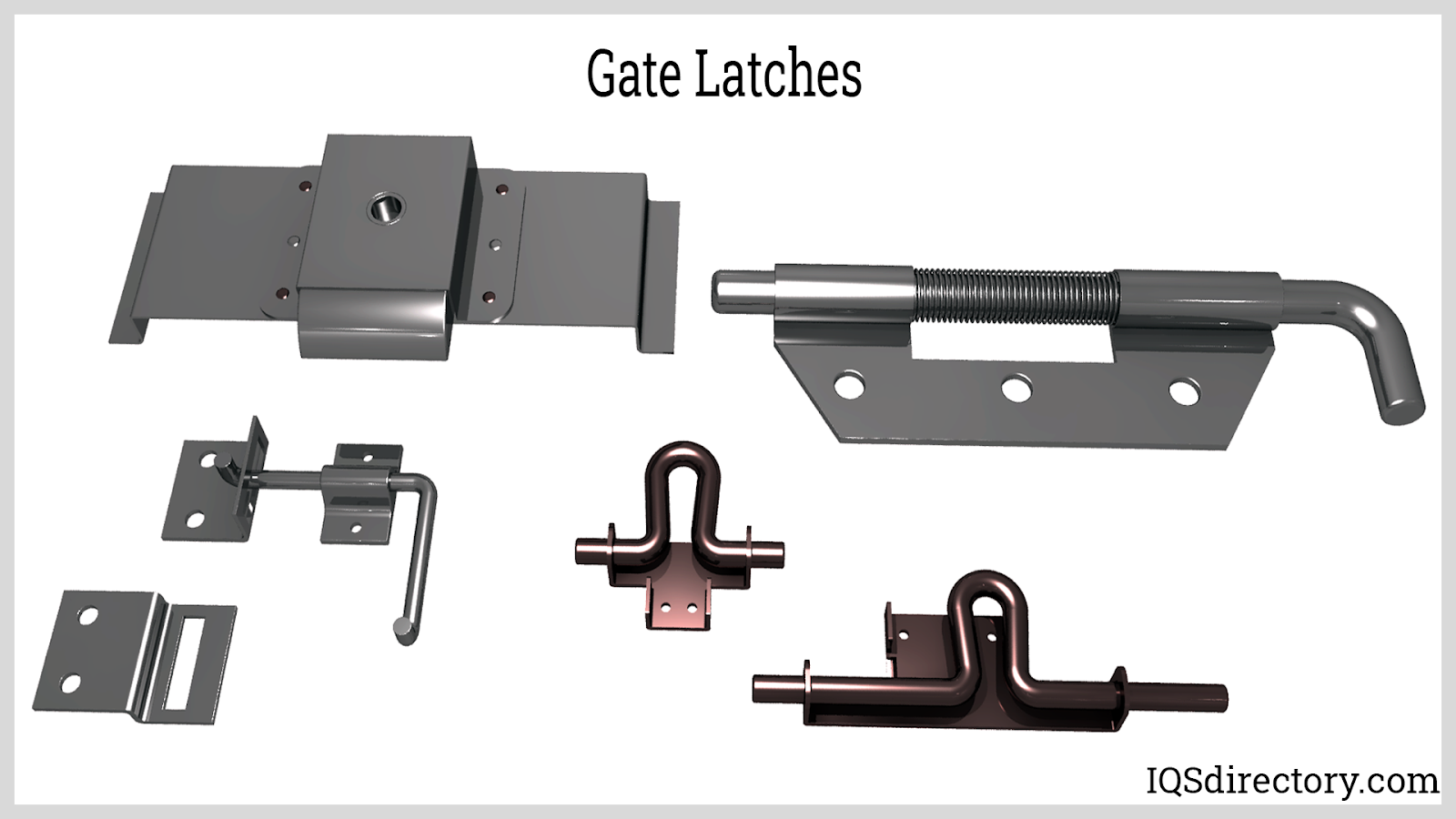

Rotary latches, also known as slam latches, are a secure and easy method for closing doors, cabinets, and cupboards. They lock in place by being forced or pushed against a striker that is a rod, round solid cylindrical shaft, or U-shaped bracket secured to the frame of an opening. Read More…

Cabinet latches are our specialty! We are located in Torrington, CT but we are committed to serving our customers wherever they may need us! All of our products go through extensive and intensive testing to ensure that we are providing our customers with only the best possible products. For more information on what we can do for you visit our website today or get in touch via email or telephone!

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

At PROTEX® we offer light to heavy-duty fasteners, handles, flush latches, case fittings, bandclamps, catch plates and more. We manufacture a large range of over centre fasteners often known as draw latches/toggle clamps/catches/over centre toggle fasteners.

More Rotary Latch Manufacturers

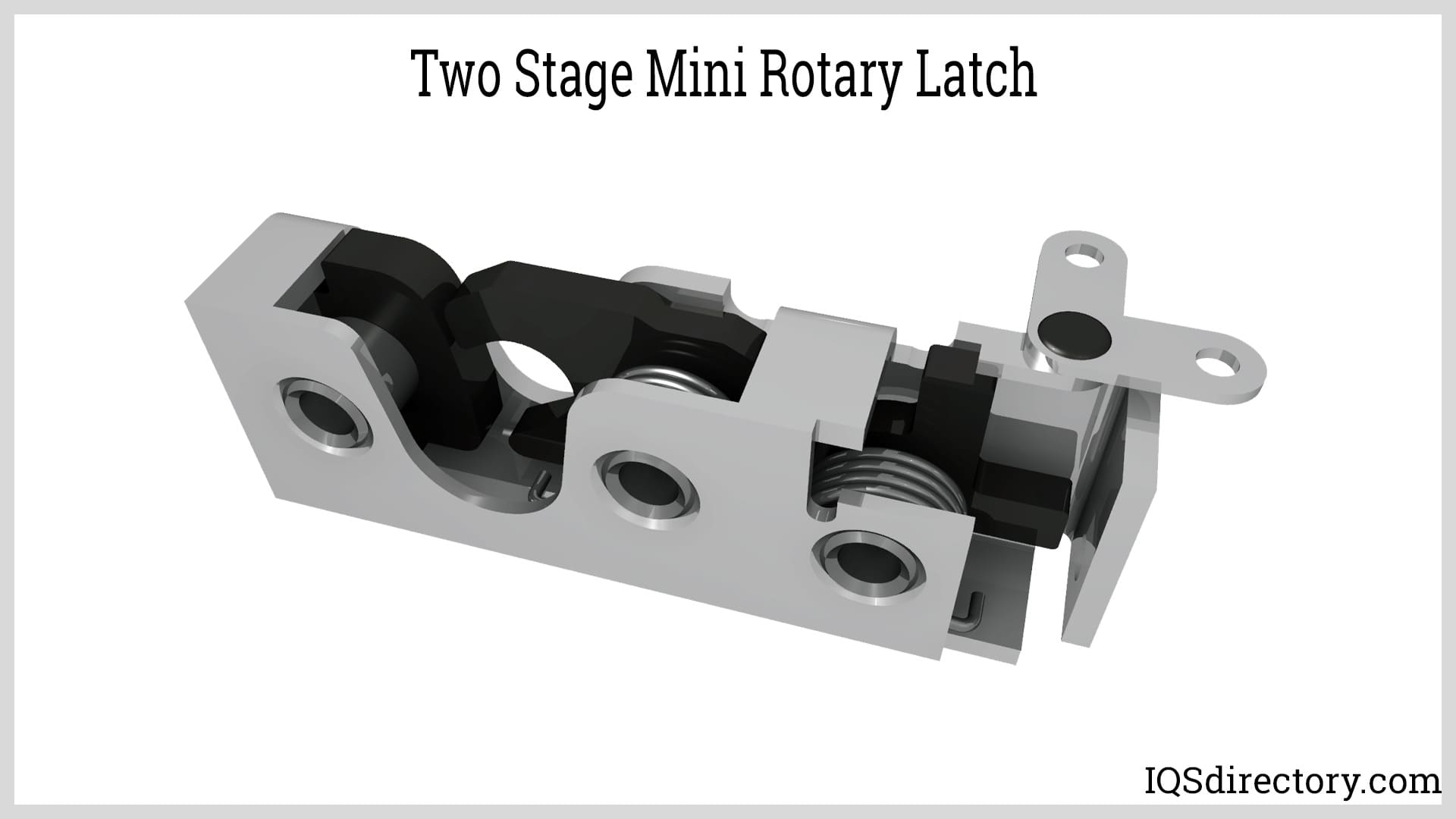

The basic structure of rotary latches includes jaws, a lever, and spring, all of which are enclosed in a housing that is mounted on an opening. Rotary latches are categorized as slam latches due to their method of closing and locking.

The basic types of rotary latches are double, single, and one or two stage. Each type has an actuator that is attached using a rod or cable that disengages the latch and releases the rotary latch to open an enclosure. The types of actuators include push buttons, handles, wires, and knobs, which vary in accordance with how secure an enclosure needs to be.

Components of a Rotary Latch

Rotary latches have been used for many years due to their dependability and strength. They are used in car doors because of their automatic locking mechanism, which prevents a door from accidentally opening. The durability and reliability of rotary latches begin with the materials used to produce them, which vary from highly resilient plastics to zinc, steel, and aluminum. The security requirements of an enclosure determine the type of materials used to produce rotary latches.

Latch

The latch of a rotary latch can have a one or two-stage latching mechanism, a factor that is determined by how secure an enclosure needs to be. Of the two stages, two-stage latches are more secure, prevent accidental openings, and are difficult to break. The engagement mechanism of a rotary latch is its rotors with one-stage rotary latches having one rotor while two-stage rotary latches have two rotors. The rotor is the part of the latch that engages with the striker and secures an opening.

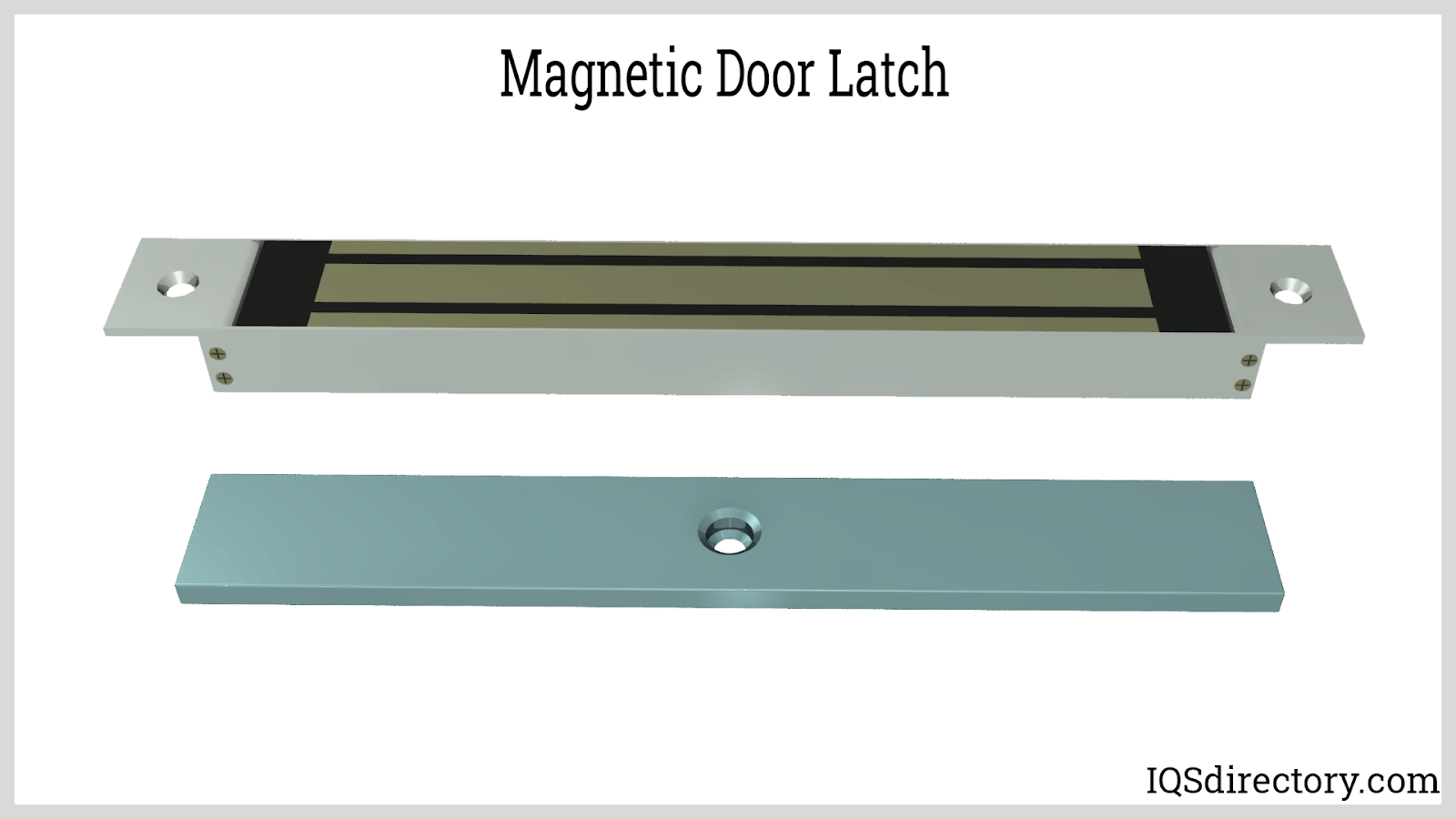

Striker

The striker is connected to the frame of an opening and is the part of a rotary latch system to which the rotor and rotary latch connect. There are several shapes and forms of strikers with the most common being in the shape of a solid rod or cylinder. The striker is securely attached to the fame of an enclosure to keep it from loosening or shifting.

An alternative form of striker is a U-shaped bracket that is connected to a flat metal plate with holes drilled for screws. This type of striker can be one solid molded piece or a metal piece with the U-shaped bracket welded to it. Both types of strikers have to be exceptionally durable due to the multiple times an enclosure is opened, closed, and locked. The strength and security of the striker is essential for the performance of a rotary latch since it prevents accidental openings or break ins.

Actuator

The actuator is the interface between the user and their rotary latch. They come in a wide range of forms and a variety of mechanisms. The strength and configuration of the actuator depends on the requirements for securing an opening with more sophisticated actuators being used for high security applications.

There are various factors used to determine the type of actuator with the first factor being whether the actuator will be inside a rotary latch or outside with inside actuators being pulls or push buttons that are flush to the surface of the opening. Outside actuators are flush mounted, surface mounted, push handles, or push buttons and can include key code mechanisms.

How Rotary Latches are Manufactured

Die casting, forging, and stamping are methods used to produce rotary latches, which are metal forming and shaping processes. Each of the components for a rotary latch are formed and shaped separately and assembled by welding and screwing. The assembly of rotary latches is critical to the performance of a rotary latch and requires that each component be tightly affixed to the housing.

Stamping

Several of the components used for producing rotary latches are manufactured using stamping, which involves punching, embossing, and die stamping sheet metals. Parts for rotary latches are made by deforming metal sheets to create the required shapes. It is a quick and efficient process that produces high tolerance components, a necessity for rotary latches.

Forging

Much like stamping, forging is a method of manufacturing that uses compressive force to shape metals. It involves machines that can apply several tons of pressure on strong and durable metals to deform them. The term forging is a generic term that refers to several different methods of forging with closed and open die and upset forging being the most common methods. Parts for rotary latches produced by forging normally require some form of secondary processing to achieve their required tolerances.

Casting

Casting is completely unlike forging and stamping and involves the use of molten materials that are poured into a die cavity. The process of casting takes many forms and is capable of producing any shape using permanent or temporary molds. Ingots, billets, or slabs of metals are melted to their molten form and poured into a mold for the formation of metal rotary latch components. The same process is used for forming components for plastic rotary latches.

Conclusion

Rotary latches have been used for many years as a secure and dependable form of locking and securing cabinets, doors, lockers, cupboards, and chests. They are one of the most reliable methods for ensuring an enclosure is secure and closed. The wide use of rotary latches has made them an essential part for guaranteeing that items are locked away and out of reach.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

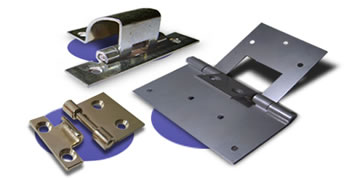

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services