Stainless steel latches are steel-made devices that are used on gates, doors, and medical equipment to securely close them. They can be installed on gates and doors and they are widely found in a variety of outdoor applications including agricultural and construction doors and gates. This is because stainless steel latches are very durable and resist harsh weather conditions. Read More…

Cabinet latches are our specialty! We are located in Torrington, CT but we are committed to serving our customers wherever they may need us! All of our products go through extensive and intensive testing to ensure that we are providing our customers with only the best possible products. For more information on what we can do for you visit our website today or get in touch via email or telephone!

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

At PROTEX® we offer light to heavy-duty fasteners, handles, flush latches, case fittings, bandclamps, catch plates and more. We manufacture a large range of over centre fasteners often known as draw latches/toggle clamps/catches/over centre toggle fasteners.

More Stainless Steel Latch Manufacturers

There are many different types of stainless steel latches available on the market today, including the stainless steel locking slam latch, stainless steel over-center draw latch, stainless steel compression latch, and more. These robust and corrosion-resistant latching solutions are commonly used in a wide range of industries, from construction and marine to food processing, transportation, and medical equipment. If you're searching for durable, high-performance latch systems or want to evaluate the best stainless steel latch for your application, understanding their types, uses, and benefits can help you make informed purchasing decisions.

What Makes Stainless Steel Latches?

Stainless steel latches are precision-engineered fastening devices manufactured primarily from stainless steel alloys. Stainless steel is an iron-based alloy that includes elements such as silicon, chromium, carbon, manganese, and often molybdenum and nickel. Every stainless steel grade contains at least 10% chromium, which plays a critical role in the alloy’s renowned corrosion resistance. Chromium interacts with oxygen to form a stable, invisible layer of chromium oxide on the surface—a corrosion-fighting film that protects the underlying metal from rust, even in challenging environments. This unique property makes stainless steel latches ideal for environments where exposure to moisture, chemicals, or salt is common, such as marine hardware, outdoor enclosures, and industrial applications.

Looking to compare stainless steel latch materials? Popular grades such as 304 and 316 stainless steel are frequently used for latches, with 316 offering enhanced corrosion resistance for marine and chemical environments. If you're curious about which grade is right for your application, explore the properties and performance differences between 304 vs. 316 stainless steel latches.

Types of Stainless Steel Latches

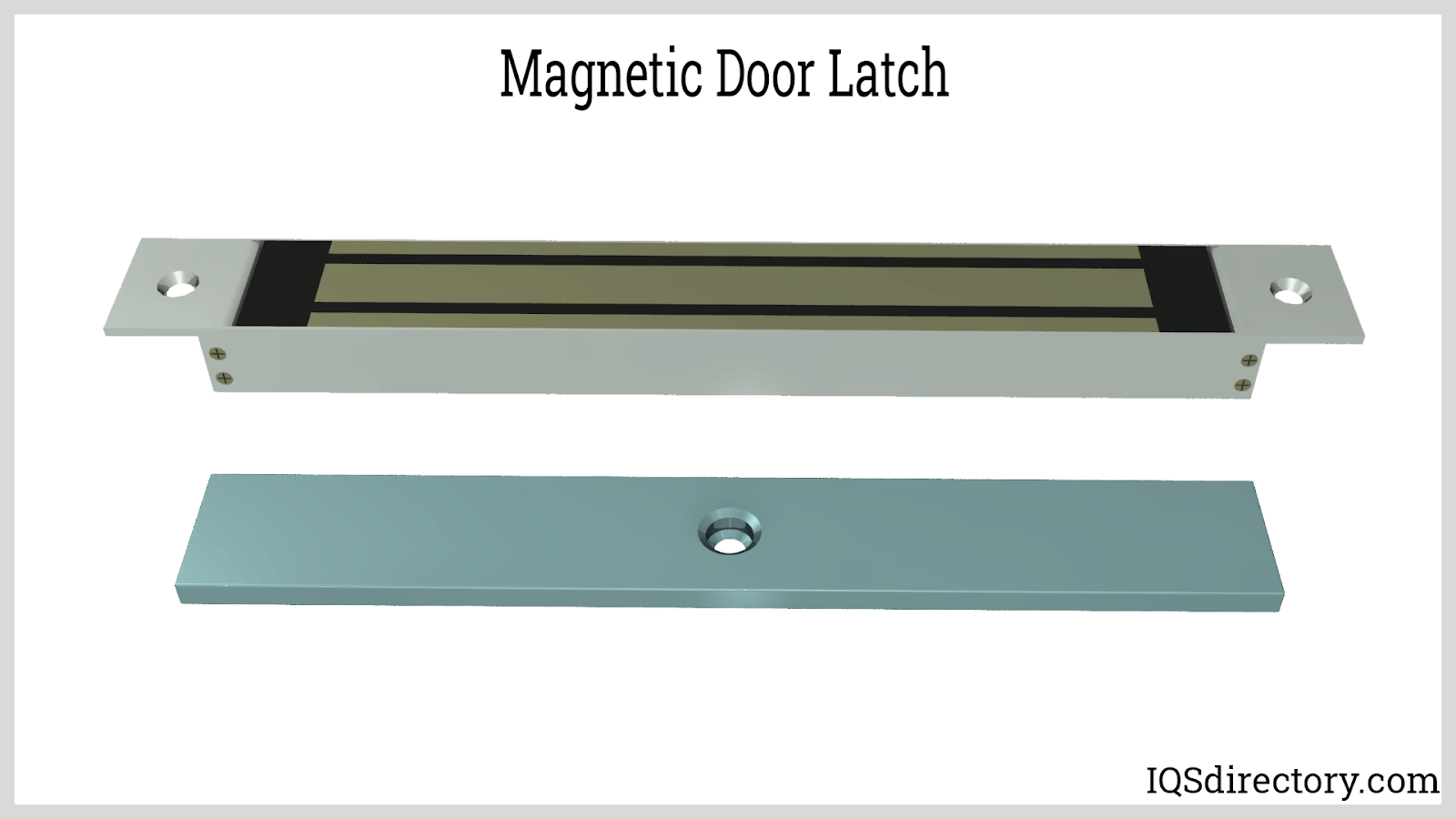

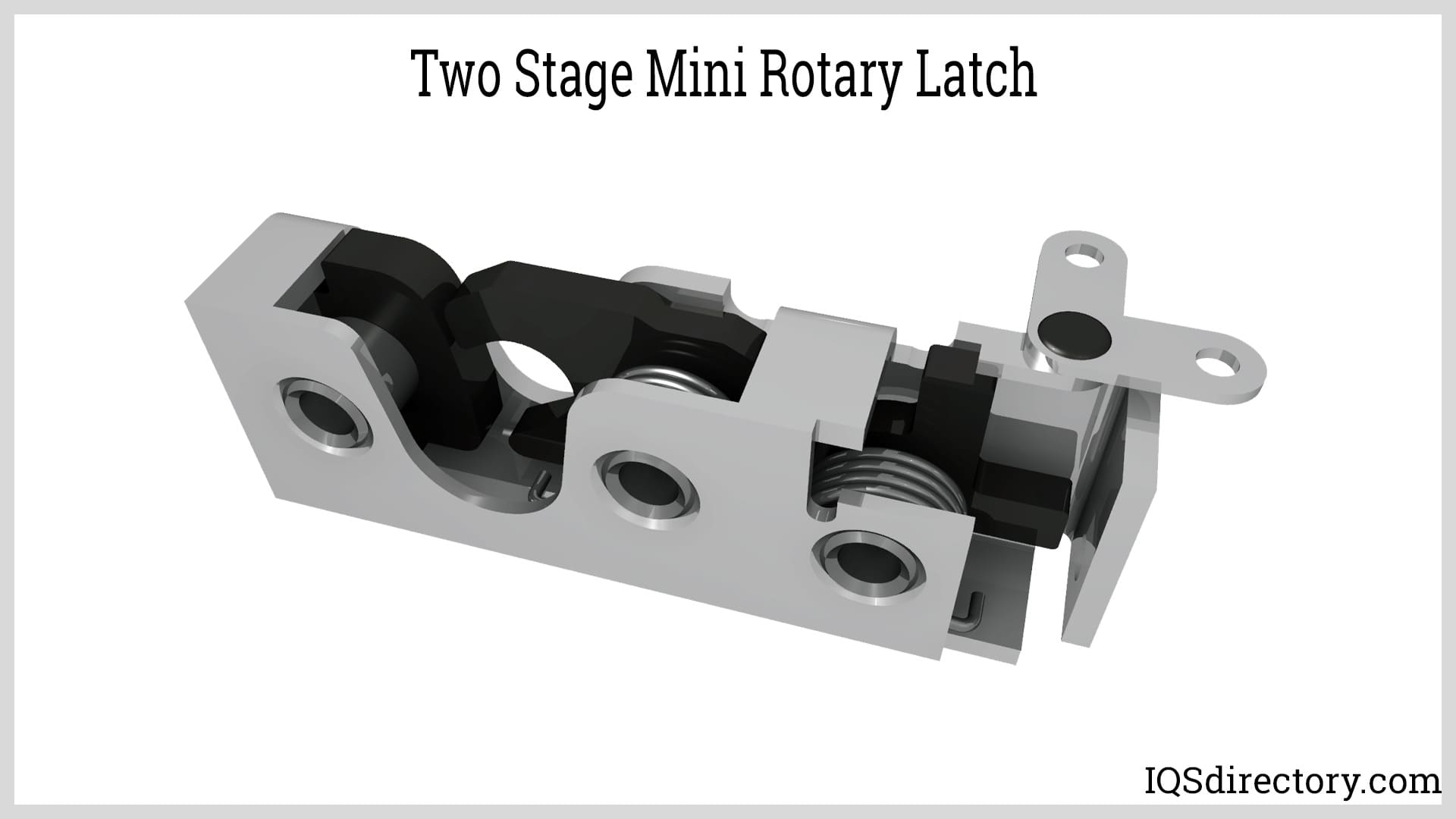

Stainless steel latches come in a variety of designs to suit different doors, panels, gates, and access points. The most common types of stainless steel latches include:

Stainless Steel Tubular Latches

Stainless steel tubular latches, sometimes referred to as mortice latches, are among the most widely used latching mechanisms for internal doors. Their name is derived from the installation method, as the tubular latch body is morticed (recessed) into the door edge. A door knob or lever handle actuates the latch mechanism to allow entry or exit. These latches are popular in residential, commercial, and institutional interiors for their reliable operation and discreet installation.

Stainless Steel Flat Latches

Stainless steel flat latches share a similar form factor and installation method with tubular latches, as both are embedded within the structure of the door. However, flat latches are specifically designed for heavy-duty doors where a locking mechanism may not be required. Their robust construction and simple operation make them well-suited for industrial settings, warehouse doors, and commercial entryways that require a strong yet straightforward latching solution.

Stainless Steel Roller Bolt Latches

Roller bolt latches, often crafted from stainless steel for extra durability and corrosion resistance, are installed within the door edge and operate via a spring-loaded roller mechanism. When the door is closed, the roller compresses and then springs into place to hold the door shut. A handle or knob retracts the roller for easy opening. These latches are available in various sizes and are commonly found in light commercial, hospitality, and high-traffic residential applications.

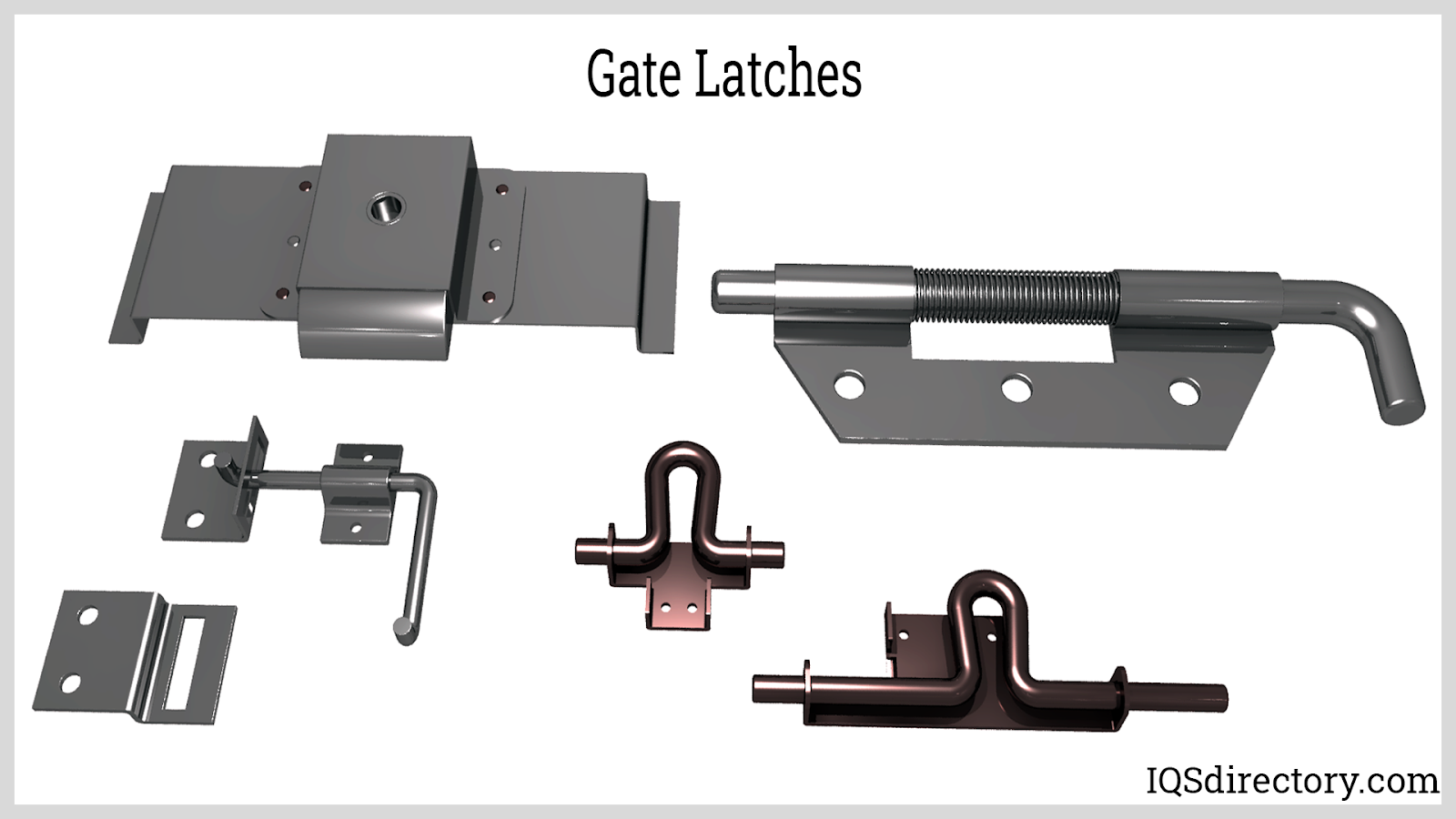

Stainless Steel Sliding Bolt Latches

Stainless steel sliding bolt latches, also known as barrel bolts or manual slide latches, are reliable and easy-to-operate security devices. They feature a sliding metal bolt that can be manually moved into a keep or strike plate to fasten gates, doors, or storage compartments securely. For unlocking, the bolt is simply retracted to release the latch. Thanks to their simplicity and toughness, sliding bolt latches are a top choice for gates, storage sheds, lockers, and outdoor fencing.

Stainless Steel Slam Latches

Slam latches are designed for fast, hands-free closing and secure retention. When the door or panel is pushed shut, the latch automatically engages, providing a strong hold without the need for manual locking. Stainless steel slam latches are commonly used in transport vehicles, industrial cabinets, and access panels where frequent, rapid closure is required.

Stainless Steel Compression Latches

Compression latches provide both locking security and vibration-resistant closure. When actuated, the latch cam compresses a gasket or seal, ensuring a tight fit that protects against dust, water, and vibration. Stainless steel compression latches are ideal for electrical enclosures, HVAC access panels, marine storage lockers, and other demanding environments.

Stainless Steel Over-Center Draw Latches

Over-center draw latches, often fabricated from stainless steel, use a cam-action mechanism to draw two surfaces tightly together when engaged. These latches are widely used for securing machine covers, toolboxes, transport cases, and industrial equipment doors where a firm, vibration-resistant hold is necessary.

Other Stainless Steel Latch Types

Additional latch designs include toggle latches, spring latches, hook latches, and paddle latches. Each style offers specific features and advantages depending on the application. When selecting a stainless steel latch, consider factors such as required holding force, ease of use, locking features, and environmental exposure.

Applications of Stainless Steel Latches

- Outdoor and Marine Use: Stainless steel latches are ideally suited for outdoor applications such as gates, fences, and marine enclosures, due to their superior resistance to rust, moisture, and salt spray.

- Residential and Commercial Doors: These latches are commonly installed on interior and exterior doors, offering security and longevity in high-traffic areas.

- Industrial and Agricultural Equipment: Stainless steel latches are trusted in the agricultural and construction industries to secure equipment panels, hatches, and storage compartments exposed to harsh conditions.

- Medical and Laboratory Equipment: Thanks to their hygienic properties and ease of sterilization, stainless steel latches are used on medical storage boxes, first-aid kits, autoclaves, and laboratory refrigeration equipment.

- Transportation and Automotive: These latches are integral to the safety and security of transport vehicles, cargo compartments, utility trucks, and trailers, where vibration resistance and tamper-proof design are essential.

- Food Processing and Commercial Kitchens: Stainless steel latches help meet food safety regulations, as they are easy to clean, non-reactive, and resistant to bacterial buildup, making them perfect for food storage enclosures and kitchen equipment.

Wondering where stainless steel latches can best serve your industry? Ask yourself: What environmental conditions must my latches withstand? Consider the unique requirements of your application—such as exposure to chemicals, humidity, or physical impact—when selecting the right latch type and grade.

Benefits of Stainless Steel Latches

The many advantages of choosing stainless steel latches for your project or facility include:

Exceptional Corrosion Resistance

Stainless steel latches are engineered to maintain their integrity and performance, even when exposed to prolonged contact with water, humid air, or corrosive agents. Unlike traditional steel or brass latches, stainless steel varieties do not rust, even in marine, coastal, or industrial environments with high salinity or chemical exposure. This makes them the preferred choice for outdoor gates, marine hardware, and chemical processing equipment.

Modern Aesthetic Appeal

One of the standout features of stainless steel latches is their ability to preserve a sleek, modern appearance over time. While other materials may tarnish, fade, or become discolored, stainless steel retains its luster and visual appeal. Properly finished stainless steel latches can enhance the look of residential entryways, contemporary office interiors, or upscale commercial properties, contributing to an overall sense of quality and professionalism.

Long-Lasting Durability

Known for exceptional strength and shock resistance, stainless steel latches offer a virtually unmatched lifespan compared to other fastening solutions. Their robust construction allows them to withstand frequent use, high impact forces, and extreme temperatures, minimizing the need for replacements and reducing operational downtime.

Minimal Maintenance Requirements

Stainless steel latches are incredibly easy to maintain. Routine cleaning with soap, mild detergent, or water is typically sufficient to preserve their appearance and function. Avoid using harsh, abrasive, or chlorine-based cleaners, as these can damage the protective chromium oxide layer. Instead, use a soft cleaning cloth or sponge, and clean the latches at least once a month or as needed based on environmental exposure. This simplicity translates into lower maintenance costs and greater peace of mind for property owners and facility managers.

Hygienic and Safe for Sensitive Environments

Stainless steel is a non-porous material, which prevents the accumulation of bacteria and dirt on latch surfaces. This makes stainless steel latches particularly advantageous in medical, laboratory, and food processing environments, where cleanliness and sterilization are paramount. Their compatibility with autoclave and chemical sterilization processes further enhances their suitability for critical hygiene applications.

Fully Recyclable and Eco-Friendly

Stainless steel is 100% recyclable, and a significant proportion of new stainless steel products are manufactured from reclaimed material. By choosing stainless steel latches, buyers directly contribute to environmental sustainability and resource conservation. If your organization values green building practices or LEED certification, specifying stainless steel hardware can support your sustainability goals.

Security and Tamper Resistance

Many stainless steel latch designs, especially compression latches, slam latches, and over-center draw latches, offer enhanced security features such as locking mechanisms, tamper-proof fasteners, and vibration resistance. These characteristics help prevent unauthorized access and ensure the safety of sensitive equipment or property.

Versatility and Customization

Stainless steel latches are available in a wide range of sizes, finishes (such as brushed, polished, or powder-coated), and configurations to meet the specific needs of different industries and projects. Manufacturers often provide custom latch solutions, including specialty mounting options, reinforced components, and integrated locking systems for unique requirements.

How to Choose the Right Stainless Steel Latch

When selecting a stainless steel latch, consider the following decision factors to ensure optimal performance and value:

- Corrosion Resistance: Evaluate the environment where the latch will be installed—marine, industrial, outdoor, or hygienic settings may require higher-grade stainless steel (e.g., 316 over 304).

- Load and Holding Strength: Consider the weight and stress the latch must handle, especially for heavy doors, gates, or industrial equipment.

- Locking and Security Features: Determine if you need a latch with integrated locks, tamper-proof designs, or keyed access for added protection.

- Ease of Installation and Operation: Assess whether you prefer surface-mount or embedded installation, and choose latch types that are user-friendly and reliable for your staff or users.

- Compliance and Certifications: For food, medical, or safety-critical applications, ensure the latches meet relevant regulatory standards and certifications.

- Cost and Value: Balance the upfront investment with the expected lifespan, maintenance requirements, and replacement costs of different latch options.

Searching for the best stainless steel latch manufacturers? Compare top suppliers based on product range, material expertise, customization options, and customer support. Need technical advice on which latch suits your application? Request product datasheets or consult with a latch expert for tailored recommendations.

Choosing the Right Stainless Steel Latch Manufacturer

To ensure you achieve the best results when purchasing stainless steel latches, it’s critical to select a trusted stainless steel latch manufacturer with a proven track record of quality, reliability, and service. Using our comprehensive directory of stainless steel latch manufacturers, you can:

- Review detailed company profiles that highlight areas of experience, manufacturing capabilities, and industry certifications.

- Quickly evaluate product specialties and service offerings using our patented website previewer—see what makes each manufacturer unique.

- Use our simple RFQ (Request for Quote) form to contact multiple stainless steel latch companies simultaneously with your requirements, saving time and streamlining the purchasing process.

- Reach out directly to manufacturers for technical information, custom order requests, or to request product samples.

Looking for competitive pricing, fast lead times, or custom engineering support? Contact several stainless steel latch suppliers through our directory to compare quotes and capabilities before making your decision. Our platform is designed to help you find the best stainless steel latch solution—whether you need off-the-shelf products or a fully customized latch system for your unique application.

Frequently Asked Questions About Stainless Steel Latches

What is the difference between 304 and 316 stainless steel latches?

304 stainless steel offers excellent corrosion resistance for general indoor and outdoor use, while 316 stainless steel contains added molybdenum for superior performance in marine and chemical environments. If you require maximum resistance to saltwater or aggressive chemicals, opt for 316-grade latches.

How do I maintain stainless steel latches in harsh environments?

Regularly clean latches with mild detergent and water, avoid abrasive cleaners, and inspect for buildup or signs of wear. For best results in coastal or industrial settings, choose electropolished or passivated finishes to enhance corrosion protection.

Can stainless steel latches be used for food processing equipment?

Yes! Stainless steel latches are ideal for food processing, storage, and kitchen equipment due to their hygienic, non-reactive, and easy-to-clean properties. Ensure the latch design meets applicable food safety standards (such as NSF certification).

What are common locking mechanisms for stainless steel latches?

Locking options include keyed locks, padlockable hasps, cam-action mechanisms, and tool-accessible fasteners. For anti-tamper applications, look for latches with integrated security features.

Can I get custom stainless steel latch solutions?

Many manufacturers offer custom latch design services, including special sizes, finishes, and mounting options to suit specific project requirements. Contact suppliers directly to discuss your needs and request engineering support.

Next Steps: Find Your Stainless Steel Latch Solution

Ready to source the best stainless steel latch for your project? Browse our directory of leading stainless steel latch manufacturers, compare features, and request quotes directly from top suppliers. Whether you need latches for doors, gates, machinery, or specialized equipment, our platform connects you with the industry’s most trusted names. Start your search today and ensure your facility benefits from the unmatched durability, security, and performance of stainless steel latches.

Still have questions? Contact us for expert guidance or explore our resources to learn more about stainless steel latch specifications, installation tips, and product selection best practices.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services